7 Ways Engineers Can Maximize the Advantages of Photo Etching

Published by

Kathleen Stillman

on

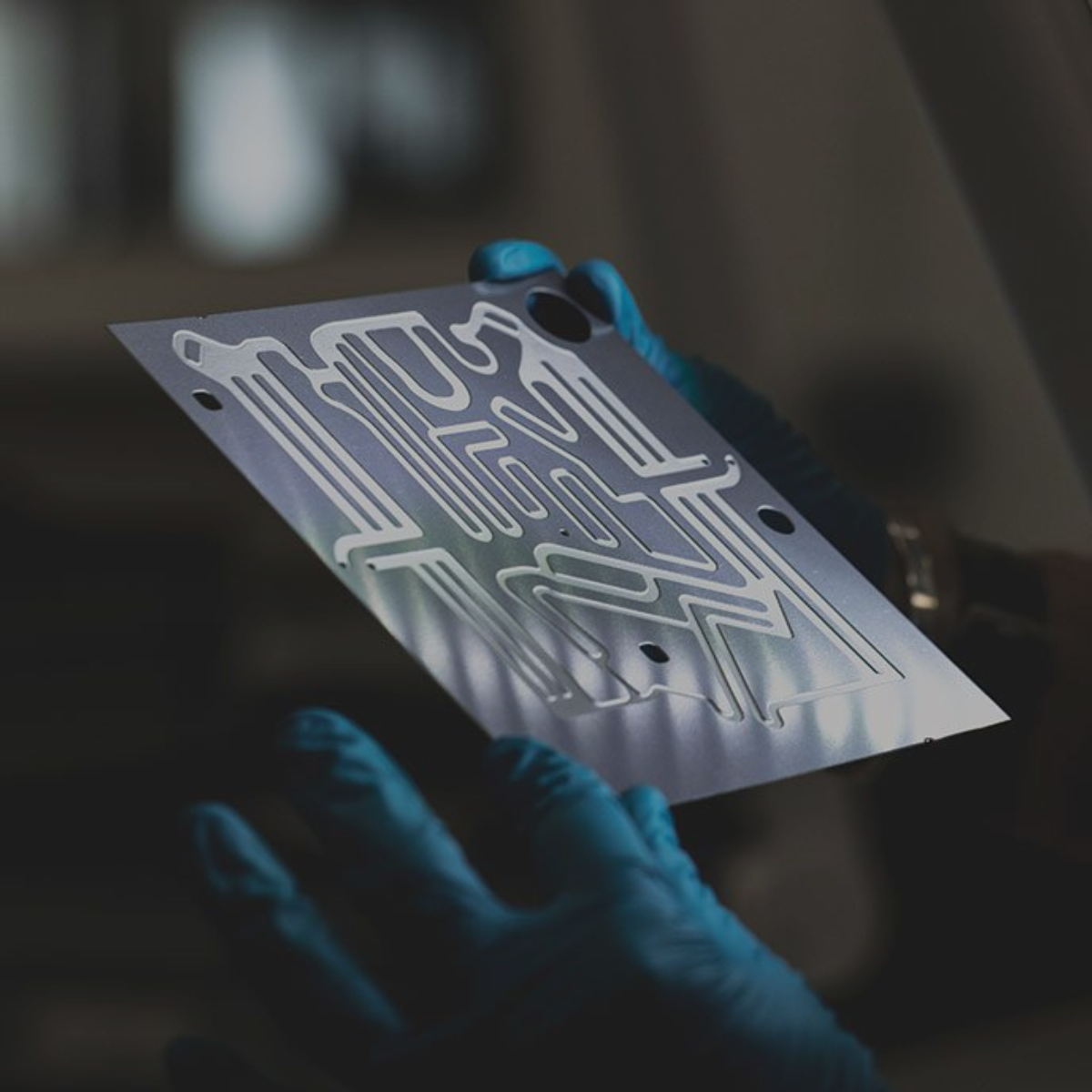

Photo Chemical Machining (PCM), also known as photochemical etching, is a highly precise manufacturing process used to produce complex metal parts with tight tolerances. Designers and engineers can take better advantage of this process by considering the following strategies:

1. Design for PCM

- Optimized Geometry: Design parts that take full advantage of the 2D nature of PCM. Complex shapes, intricate patterns, and thin-walled structures are easier, faster and more economical to produce with this method compared to conventional machining.

- Uniform Material Thickness: Ensure that the metal thickness is uniform across the part. PCM works best on sheets with consistent thickness as it ensures uniform etching depth.

- Avoid Sharp Corners: Use rounded internal corners to prevent undercutting and to maintain the strength of the part.

- Feature Scaling: Understand the minimum feature size that PCM can achieve with the chosen material and design parts accordingly. Small holes, fine lines, and thin sections should be designed within the process's capability. Typically holes and other through-cut features need to be 110% greater than the material thickness.

2. Material Selection

- Material Compatibility: Choose materials that are well-suited for PCM. Metals like stainless steel, copper, nickel, and their alloys are commonly used. Ensure that the material has consistent etching properties. You can find more information here.

- Surface Finishes: Take advantage of PCM's ability to create burr-free and smooth edges, which reduces the need for post-processing.

- Material Thickness: Thicker materials might require longer etching times or multiple passes, which could affect precision. Select appropriate material thickness to balance strength and ease of etching.

3. Tolerance and Precision Considerations

- Realistic Tolerances: Set tolerances that are achievable with PCM. While PCM offers high precision, extremely tight tolerances may require additional steps or other processes.

- Dimensional Accuracy: Consider that the etching process can cause slight dimensional changes, especially in large or complex parts. Designing with this in mind helps achieve desired outcomes without extensive trial and error.

4. Cost Efficiency

- Batch Production: PCM is particularly cost-effective for producing large quantities of small, intricate parts. Design components that can be produced in batches to maximize efficiency.

- Tooling Costs: Since PCM uses phototools instead of hard tooling, it offers flexibility for design changes. Take advantage of this by refining designs iteratively without significant cost implications.

5. Prototyping and Testing

- Rapid Prototyping: Use PCM for rapid prototyping of designs. This process allows quick iterations to test and refine designs before committing to large-scale production.

- Design Verification: Test small batches to verify the design and material behavior in PCM before scaling up production. This helps in identifying and correcting potential issues early in the process.

6. Integration with Other Processes

- Secondary Processes: Combine PCM with other manufacturing processes like plating, forming, or joining to enhance part functionality. Design parts that can seamlessly integrate with these processes.

- Hybrid Parts: Consider creating hybrid parts where PCM is used to produce intricate features, and other methods are used for bulk material removal or additional detailing.

7. Communication with Suppliers

- Collaborative Design: Work closely with PCM service providers during the design phase to ensure that the design is optimized for the process. Their expertise can guide material selection, phototool design, and process parameters.

- Clear Specifications: Provide detailed and clear specifications regarding material type, thickness, tolerances, and any post-processing requirements to avoid miscommunication and ensure the final product meets expectations.

Here's a 3-minute Video Animation

By aligning design and engineering practices with the strengths of PCM, you can maximize the precision, efficiency, and cost-effectiveness of producing metal parts using this method.