What Effect does Sheet Size have on the Cost of Photo Etching?

The two biggest variables affecting the cost of photo etching are metal thickness and sheet size. Metal thickness bears directly on the length of time it takes to etch through a given metal thickness measured in minutes per mil (.001) of thickness. Sheet size drives the amount of labor that accumulates.

The two biggest variables affecting the cost of photo etching are metal thickness and sheet size. Metal thickness bears directly on the length of time it takes to etch through a given metal thickness measured in minutes per mil (.001) of thickness. Sheet size drives the amount of labor that accumulates.

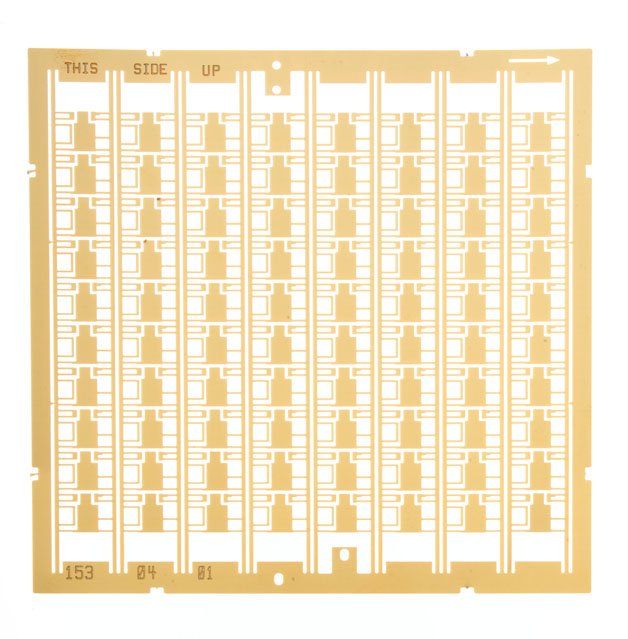

The photo etching process has seven essential steps: cutting, cleaning, laminating, printing, developing, etching and stripping. For each of these steps, a sheet of material must be handled. Each time a sheet is handled into and out of a step in the photo etching process, labor is applied. If you were loading and unloading a pizza oven, your hands wouldnt care if it was a small pizza or a large pizza. You can easily see that loading and unloading many small sheets (pizzas) consumes more labor than handling a smaller number of large sheets.

The effect of sheet size on the cost of photo etching is illustrated in the table below:

The test part is a 1 x 1 x.010 thick part. It doesnt make any difference whether the part is a simple disk (cheese pizza), a washer (pepperoni pizza), a spring form (pepperoni, sausage and mushrooms), or a screen (the works). The photo etching process doesnt care.

Prices shown do not include any material cost.

|

Sheet Size |

12 x 12 |

12 x 18 |

12 x 24 |

18 x 24 |

|

Min Tolerance |

+/-.002 |

+/-.0025 |

+/-.003 |

+/-.004 |

|

500 |

.59 |

.43 |

.41 |

.38 |

|

1000 |

.56 |

.39 |

.36 |

.31 |

|

2500 |

.52 |

.38 |

.29 |

.25 |

|

5000 |

.45 |

.33 |

.29 |

.23 |

|

10000 |

.42 |

.31 |

.27 |

.22 |

|

25000 |

.40 |

.30 |