-

What Engineers Ask Us about Photochemical Etching

It’s Always Worth A Conversation We have lots of conversations with engineers and designers who need better solutions for challenging…

-

Why We Love Photo Etching and You Should Too!

Sparkle Isn’t Everything Photo etching may not have the glamour and sparkle of laser and plasma cutting or the brute…

-

Battery Anodes and Cathodes, Battery Current Collectors, current collectors., Energy Generation and Storage, etched metal, EV batteries, Metal Etching, Photo etchingThe Benefits of Photo Etching for EV Battery Applications

Key Aspects of Using PCM For EV Battery Elements As the global transition to electric vehicles (EVs) accelerates, the demand…

-

bipolar plates, current collectors., flow fields, PEM fuel cells, photo chemical machining, Photo etchingHow Photo Etching Benefits Production of PEM Elements for Fuel Cells

PEM Fuel Cells Lead the Way In the rapidly evolving world of clean energy, proton exchange membrane (PEM) fuel cells…

-

Design Considerations for Photo Chemical Machining (PCM)

When Conventional Processes Don’t Fit The Bill… Photo chemical machining (PCM), also known as photo etching or chemical etching, is…

-

Aluminum Photo Etching, Brazing Pre-forms, Cost of Photo Etching, Metal Etching, Metal Filtration, Photo Chemical Etching, Photo Etching AluminumSupply Chain: Checklist for Photo Etching

6 Reasons to Consider Photo Chemical Machining for Precision Metal Parts Production In the fast-paced world of manufacturing, supply chain…

-

Memory Triggers for Engineers/Designers: When to Choose Photo Etching

8 Things to Remember About PCM In the world of precision metal part manufacturing, choosing the right process can make…

-

Aluminum Photo Etching, Brazing Pre-forms, Design for Manufacturing, Energy Generation and Storage, Metal Etching, Metal Filtration, Photo Chemical EtchingEssential Resources for Designers and Engineers Exploring PCM

For designers and engineers working with precision metal components, understanding the capabilities of photochemical machining (PCM) is crucial for leveraging…

-

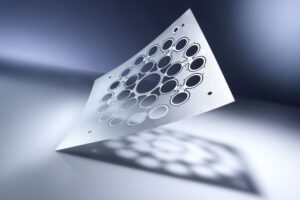

How Power Generation and Storage Systems Benefit from PCM Fabricating

Capable of Intricate Patterns and Geometries Photochemical machining (PCM), also known as photochemical etching, is a highly precise and versatile…

-

Aluminum Photo Etching, Cost of Photo Etching, Design for Manufacturing, Metal Etching, Metal Filtration, Photo Chemical EtchingExploring the Capabilities of Photochemically Machining Metal Parts

60 years of Conard Corporation’s Photochemical Machining Expertise for Precision Metal Components For designers and engineers working with precision metal…