Aluminum: Why Etchers (except us) hate it

Aluminum is a light and versatile metal. However, it has a couple of characteristics that give etching houses fits. It is highly reactive and will etch in both acids and bases. Common photoresist film is designed to repel acid, but to remove it you need to use a fairly high Ph caustic solution. And, oh darn, that etches aluminum, too. So, say bye-bye to dimensional tolerances. For many etchers, the headache isn't worth it. (And, shhh, don't tell anybody... but sometimes they come to us for aluminum.)

We were born for aluminum, really...

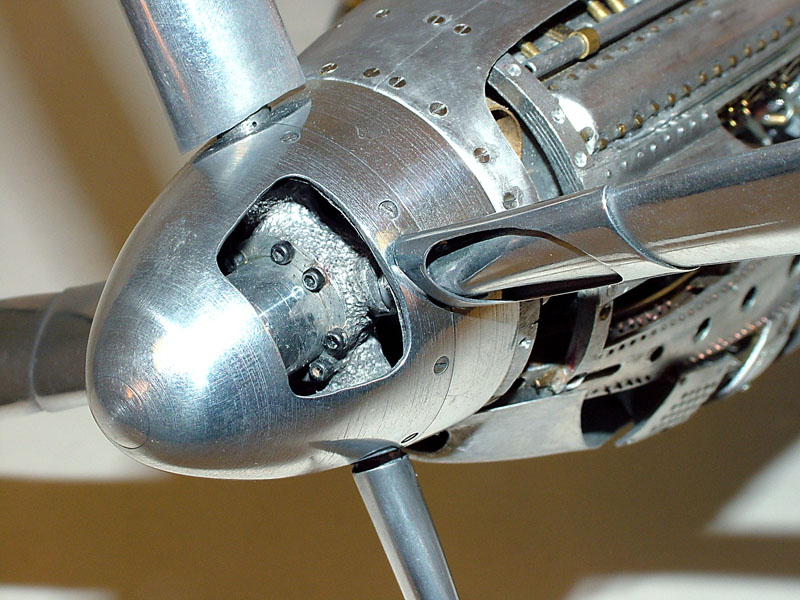

Back in the 1960s, a very well known aircraft engine maker was forging propeller hubs (yes, propellers) in aluminum. The surface finish coming out of the forging dies was less than ideal. And, back then, there were no practical machining options for refining the surface finish of a complex involute shape. Basically, advanced machine tools at the time had only digital readouts, but little --if any-- programmable functions. The available solution was to hone the hubs by hand, an arduous process at best.

A metallurgist employed by the engine maker thought it might possible to chemically hone the forged hubs. He quickly learned the same painful lessons most etchers face when dealing with aluminum. However, he persevered, gaining a deep understanding of why the process was so volatile. In yet another apocryphal story of the driven inventor working from his garage (with a loan from his mother in law), he slowly and carefully teased out the secrets to taming the reaction.

After several years of work, he succeeded in developing a reliable and controllable process for etching aluminum. His efforts did not go unnoticed, especially in the aerospace community that was increasingly embracing aluminum for its light weight and strength. And, thus, Conard Corporation was born.

In the 54 years since, Conard's reputation for and expertise in chemically etching aluminum has been a mainstay of our business. And, we're still using the process developed by Conard's founder. (Before you ask, they won't tell me what it is. Apparently, that information is locked in the vault that contains the recipes for Coca Cola and KFC's 11 herbs and spices.)

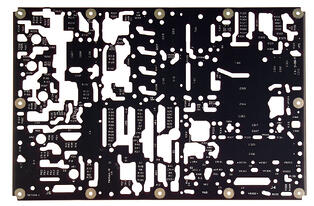

In recent years, Conard's deftness with aluminum has caught the attention of vacuum brazing facilities. Aluminum 4047 filler alloy foil is very popular for braze preforms. However, there are few fabricating methods that can handle dead-soft .001" foil with any success. Etching is a cinch for .001" material, but aluminum is aluminum, and if you can't do the thicker stuff, you have no chance with foil. But, we can.

Conquer your fear of aluminum

We have it covered, from .001" foil to .080" sheet. When you think aluminum, think Conard.

Let us help you

We were born to love aluminum, and you can, too. We would be happy to look at your project and send you a FREE quote!