What is the difference between chemical milling and chemical etching?

As an alternative to "conventional" methods, such as stamping, laser, water jet or wire EDM, chemical etching provides an accurate and economical solution for many precision metal applications.

The FREE Comprehensive Guide to Photochemical Machining provides detailed information about capabilities, specifications, design rules, cost comparisons and more: Get it here:

How It Works:

Whether in panel form or reel-to-reel, chemical etching is most often used to produce thin gauge metal parts, sometimes as thin as .0005". Panel etching can also process ferrous alloys to .040" thick, copper alloys to .065", and aluminum to .080". Photo chemical etching evolved in the 1950s from the then-nascent printed circuit board industry. By using film masters as exposure masks, chemical etching was a meaningful alternative to stamping for many metal applications.

And it still is today. The exposure masks, or photo tools, can be produced to very high resolutions on laser photo plotters, resulting in even greater precision in the parts produced. Laser direct imaging on glass tools can produce feature sizes less than 100 microns.

The range of products manufactured by photo etching continues to grow from extremely fine semiconductor packaging devices to sensor elements up to 24" x 60" and a wide variety of industrial components. Chemical etching is exceptionally well suited to manufacturing a wide variety of screens, grid, meshes, and other perforated products.

Chemical milling is a process to selectively alter the characteristics of a fabricated metal part.

Interestingly enough, chemical milling was the process for which Conard Corporation was started. In the 60s, Pratt and Whitney was forging propeller hubs in aluminum. Conard's founder, Richard Huttinger, was a metallurgist at P&W. At that time, the aluminum forging process left a less than optimum surface condition on the parts. There really wasn't a practical solution for machining these complex surfaces to a finished condition. Huttinger thought it could be done with chemicals. Working from his garage, he eventually developed an etchant that would work consistently and reliably for aluminum.

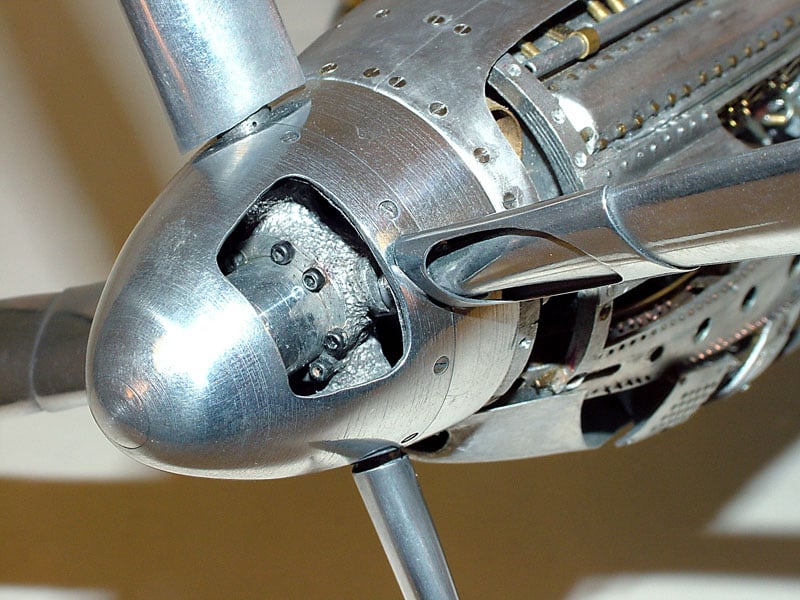

Chemical milling is often performed on three dimensional parts. Many aerospace components are chemically milled in selective areas to reduce weight without affecting the overall strength and function of the parts. Engine nacelles, cowlings and fairings are typical of the types of parts to be lightened in this fashion.

Masks for this process are usually computer-cut from pressure sensitive films similar to the vinyl films used for lettering and signage. These patterns are applied by hand to protect metal areas from the acid solution. The masked part is immersed in a tank of etchant for a period of time to affect the material removal.

The main distinction between chemical machining (etching) and chemical milling is that the machining process fabricates parts and the milling process alters parts.

Chemical milling may be subject to Nadcap checklist 7108/5.

Resources for chemical milling services.