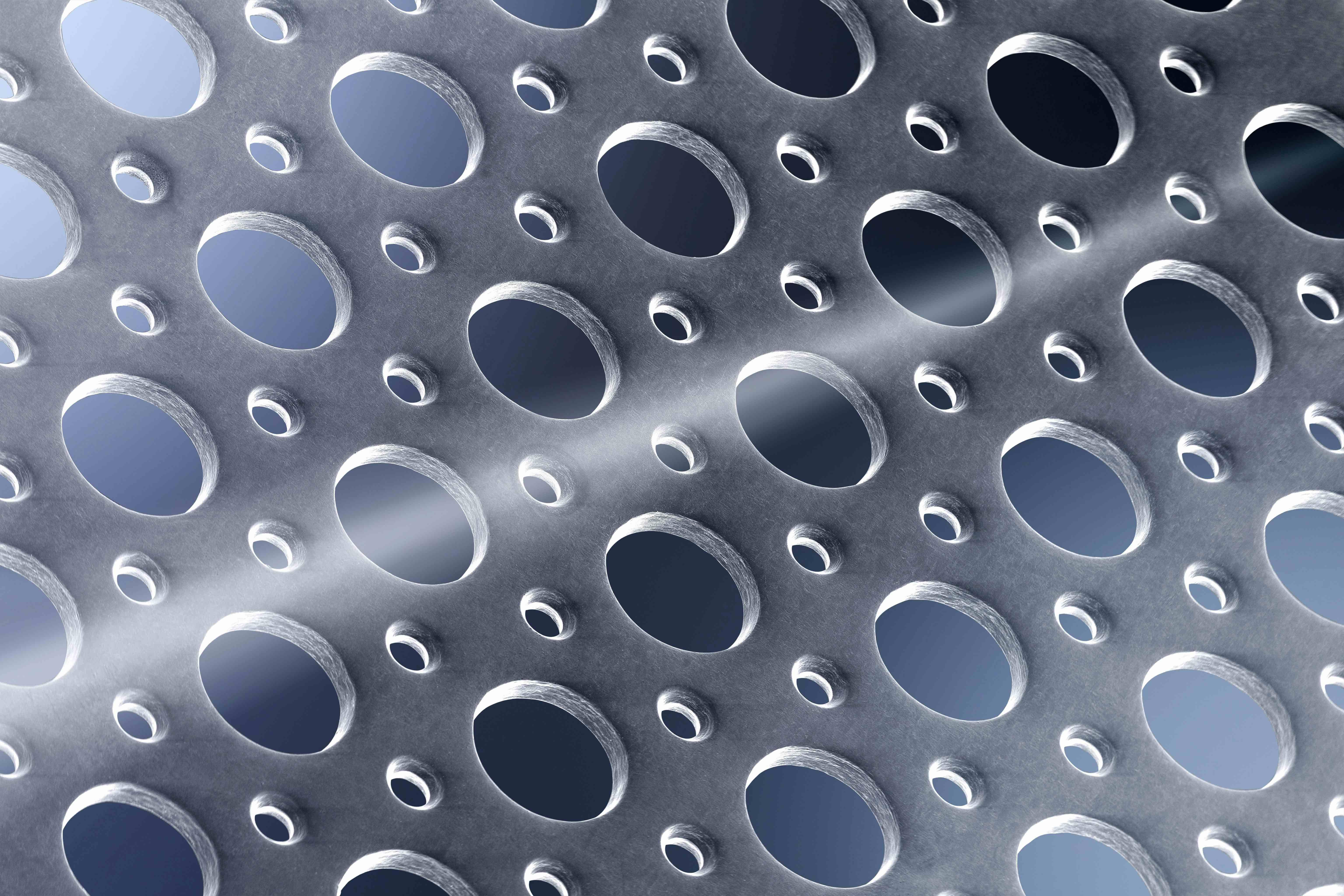

When You Need a Whole Lot of Holes...

Many engineers and designers have embraced photo etching, also known as chemical etching or photochemical machining, as their go-to option for making metal filtration, grids and screens.

Some of the benefits of etching include:

Precision and Accuracy:

Photo etching allows for high precision and accuracy in creating patterns and designs on metal surfaces. This is crucial for manufacturing filtration products with specific and complex geometries.

Fine Detail:

Designers can create fine details and intricate patterns on metal sheets that would be prohibitively difficult to produce with stamping or punching, and exceptionally expensive in cycle time for laser or plasma.

Customization:

Manufacturers can easily create perforated products with varying mesh sizes, shapes, and configurations to meet specific filtration/screening requirements.

Burr-Free and Stress-Free:

Mechanical cutting methods often require secondary processing to remove burrs. Photo etching produces burr-free and stress-free metal components. Engineers value this property as any burrs or residual stresses could affect the performance and integrity of the filters.

Material Versatility:

Photo etching is compatible with a wide range of metals, including stainless steel, aluminum, and nickel and copper alloys. Nickel and copper have become increasingly popular alloys for battery anodes and cathode

Cost-Effective for Prototyping:

For a few hundred dollars, designers can prototype multiple configurations at one time to accelerate the product development process.

Tight Tolerances:

Photo etching tolerances are typically +/- 15% of metal thickness to a practical minimum of +/-0015” for metal foils .010” thick and less.

Reduced Material Waste: The process is highly efficient and produces minimal material waste compared to traditional machining methods. This contributes to cost savings and aligns with sustainable manufacturing practices.

In summary, photo etching offers a combination of precision, customization, material versatility, and cost-effectiveness, making it well-suited for the manufacturing of metal filtration products where intricate designs and high precision are essential.

For more information, check out some of our popular resources here.