Photo Etching: Perforating With (out) a Punch

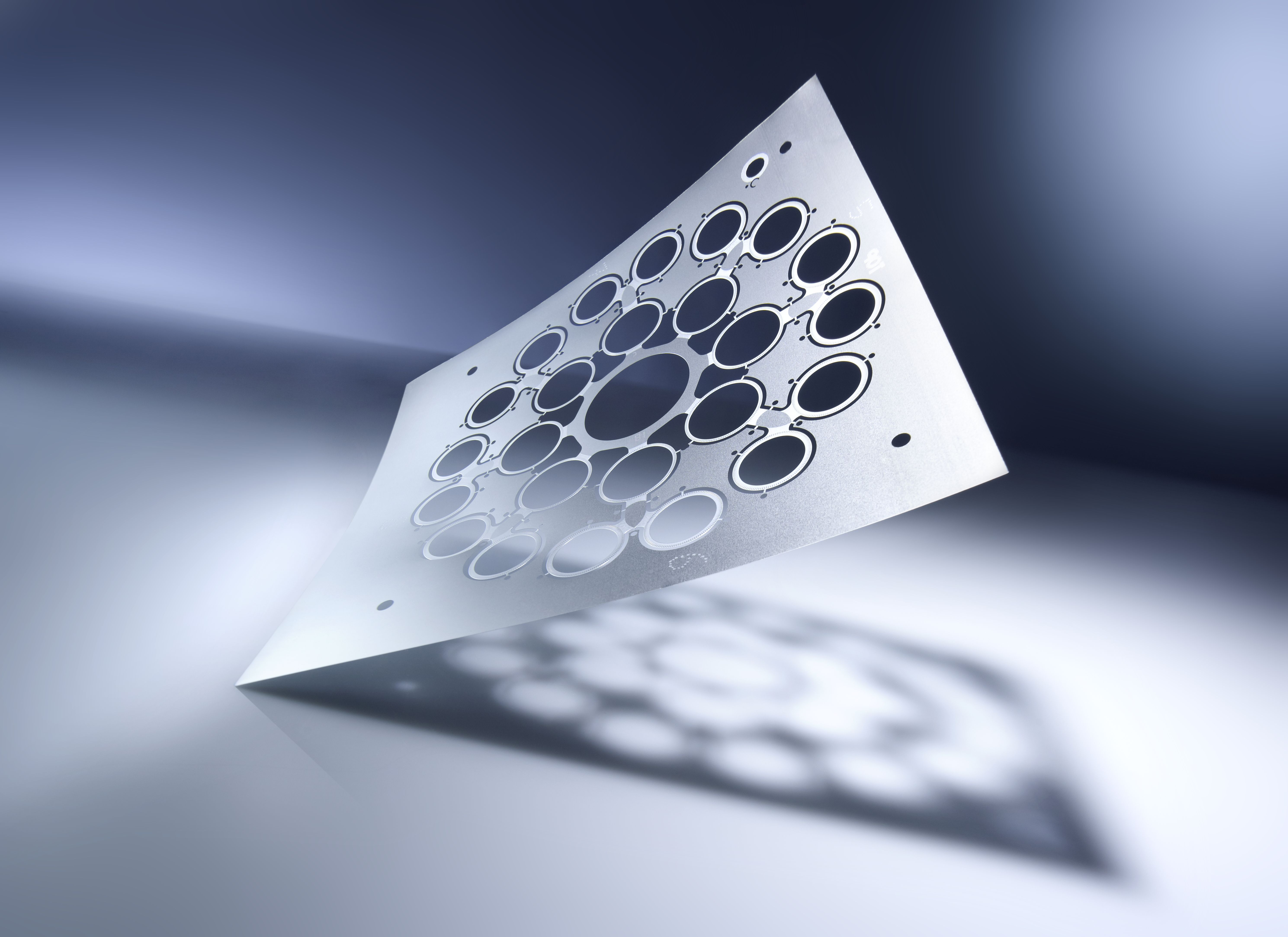

Discover the numerous advantages of photo chemical machining for manufacturing perforated metal products.

Precision and Complexity Made Simple

One of the key advantages of photo chemical machining is producing parts with complex geometries at no additional cost.

Perforated metal products, in particular, benefit from photo etching's agnosticism. One hole, a million holes-- it doesn't matter because they are all free. Lighter gauge metal screens, grids, filters , grilles and even decorative elements find applications in many industrial, scientific, medical, energy, consumer and electronic products.

Here are some household examples: coffee filters--basket, pour-over and french press- etched stainless steel. How about the foil on the electric shaver--that's etched, too. Another big- maybe not household-- application is medical stents. It is very likely that you have seen, purchased or received etched giftware or jewelry.

The chemical etching process allows for the creation of intricate patterns and designs, ensuring that each perforated metal product is manufactured to the customers' specifications.

Additionally, photo chemical machining can produce complex shapes and features that would be difficult or impossible to achieve using traditional machining methods.

This opens up new possibilities for product design and innovation, giving manufacturers the freedom to create unique and customized perforated metal products.

Cost-Effective Production

Photo chemical machining offers a cost-effective solution for manufacturing perforated metal products.

The process eliminates the need for expensive tooling or molds, as the desired pattern or design can be created directly from a digital file. This reduces setup costs and lead times, making photo chemical machining a viable option for both small-scale and large-scale production.

Although stamping will always be faster than etching, increasing design complexity is encapsulated in escalating tooling costs and lead time.

Laser-, plasma-, and water-jet cutting have their place in many areas, but perforated products aren't a good fit. These methods have to cut the holes one-by-one. In etching, the holes happen all at once.

Furthermore, the chemical etching process is highly efficient, minimizing material waste and maximizing the utilization of the metal sheet.

This results in lower material costs and increased production efficiency, making photo chemical machining a cost-effective choice for manufacturing perforated metal products.

Versatility in Design

Another advantage of photo chemical machining is its versatility in design.

The process allows for the creation of perforated metal products with a wide range of hole sizes, shapes, and patterns.

Whether it's simple round holes, complex patterns, or custom designs, photo chemical machining can accommodate various design requirements.

This versatility opens up opportunities for creativity and customization, allowing manufacturers to meet the specific needs and preferences of their customers.

Furthermore, the design flexibility of photo chemical machining enables the production of perforated metal products with different functional properties, such as enhanced airflow, light diffusion, or filtration capabilities.

Enhanced Product Quality

Photo chemical machining is known for its ability to deliver high-quality perforated metal products.

The precise and controlled nature of the chemical etching process ensures consistent and uniform results, with minimal variation from part to part.

This results in products with superior dimensional accuracy, surface finish, and edge quality.

Additionally, photo chemical machining minimizes the risk of distortion, burrs, or other common defects associated with traditional machining methods.

The high-quality finish and impeccable craftsmanship of photo chemical machining make it an ideal choice for manufacturing perforated metal products that require both aesthetic appeal and functional performance.