Quality Control in Photo Chemical Machining: Ensuring Accuracy and Consistency

The inestimable Lily Tomlin once posed the question: " if we ejected quality control from every factory in America, would quality just run rampant?"

"Control" vs "Assurance"

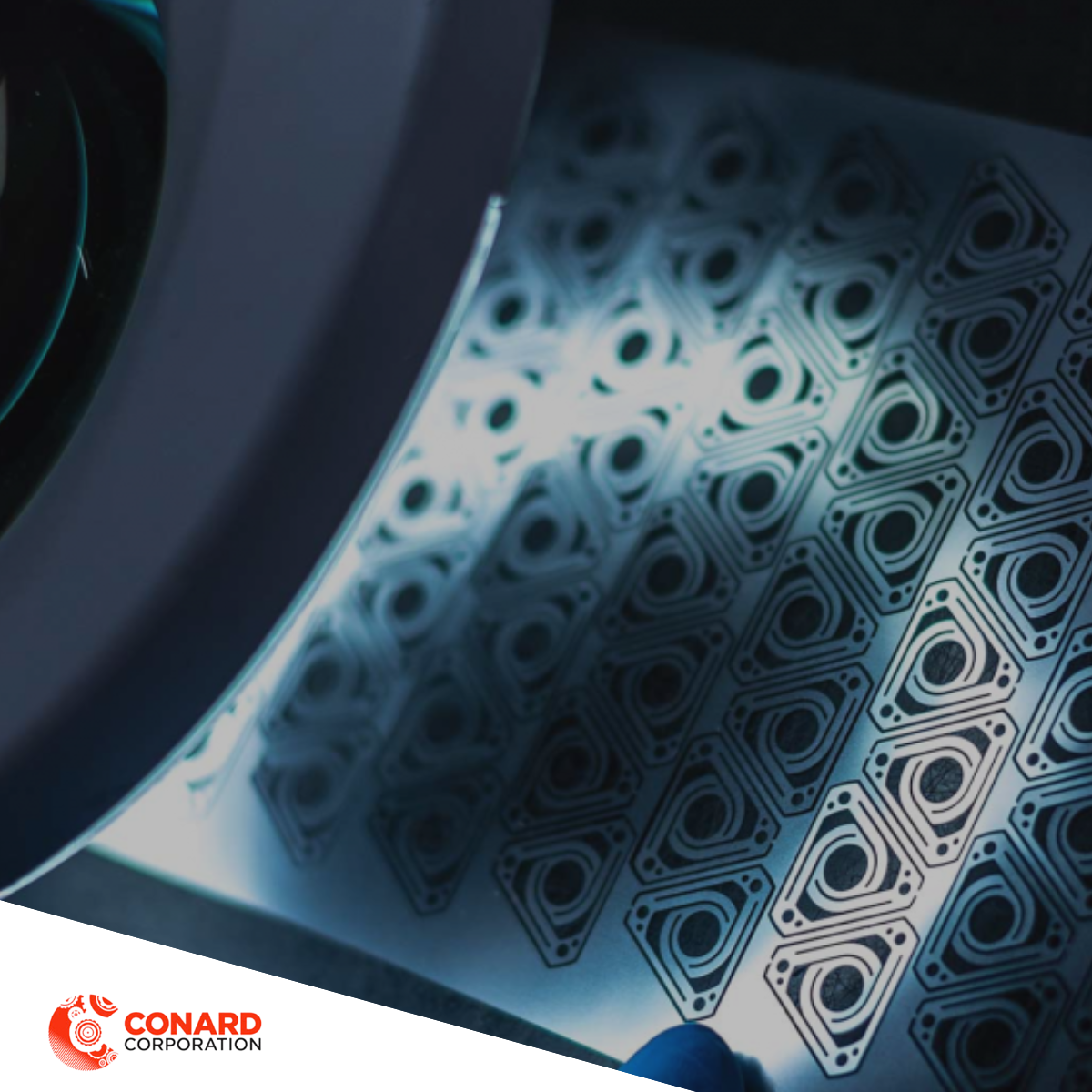

In the world of manufacturing, precision and consistency are paramount. This is especially true in processes like photo chemical machining (PCM), where intricate metal parts are created using chemical etching.

Control is a function of design. It starts with the part and its dimensions and tolerances. It continues into the careful development of a production process that can meet the specifications.

At each step in the production process- photo etching has seven key steps-there must be specific and detailed instructions about how the step is to be performed and how the work is to be validated. A key piece of that process is the training and verification of the operator(s).

The entire process and the means of executing it must be carefully planned, tested, and verified at each step. The part design feeds into the process design and the work instructions and operator training. If all of these are done properly, then the probability of success should be very high.

Assurance proves that the process succeeded. Assurance involves a series of measures and checks designed to verify that each part meets the specified tolerances, dimensions, and other requirements. It is essential for maintaining consistency across production runs and ensuring that the final products meet the customer's expectations.

Getting Ahead of the Curve

" Quality Control," in its traditional connotation, is designed to detect defective parts after manufacture. This "inspecting the quality in" leads to wasted materials, rework, and potential delays in production. By implementing robust control procedures in the design of parts and processes, and couple them with process assurance steps, manufacturers can minimize these risks and deliver high-quality parts consistently.