What is the difference between Photo Etching and Metal Stamping?

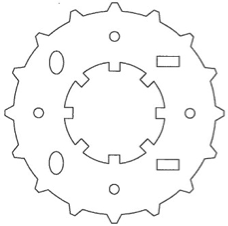

This little part recently starred in Conard's new video about photo etching. CC Star, as we call it, is 2.7 inches in diameter and is .020 thick stainless steel. Just to satisfy our own curiosity, we asked other types of metal fabricators to quote this part.

This little part recently starred in Conard's new video about photo etching. CC Star, as we call it, is 2.7 inches in diameter and is .020 thick stainless steel. Just to satisfy our own curiosity, we asked other types of metal fabricators to quote this part.

Metal Stamping

The metal stamping company quoted about $10,000 to $13,000 to make the hardened steel tooling to produce CC Star. The lead time for the tooling was 6 weeks. The cost of the phototool we would use for etching would be $235. The lead time would be one day. So far, the difference between metal stamping and photo etching is $12,765 and 41 days.

The stamping tool is kind of a big deal. Just the steel, wire EDM service and heat treating for this particular part will run between $6,000 and $9,000. The tool maker figures between 80 and 100 hours of labor for prep and assembly. A die-makers time is worth $60-$80 per hour. So, a rather strenuous undertaking to produce a smallish metal part.

Once the stamping tool is complete, it needs to be set up in a stamping press. If the stamping house has adopted SMED practices (Single Minute Exchange of Dies), the installation and alignment can be done fairly quickly. It could also be a more involved process . Once the tool is installed, set up pieces are run and the press is adjusted to produce the parts correctly.

Chemical Etching

To produce the phototool, the designer takes our CAD file and adjusts the dimensions to account for the etching allowance. Its a formulaic process where outside dimensions are made a little bigger and inside dimensions are made a little smaller by a ratio related to the metal thickness. The designer then adds connecting tabs, if required. This compensated image is stepped-and-repeated to fill a designated sheet of material. In this case, we chose an 18 x 24 sheet, which allows us to etch 48 parts per sheet. The resulting file is output to a laser photoplotter to produce 2 sheets of film at 8000 dpi resolution. The 2 films are precision aligned and punched for registration. End to end, the process takes about 2 hours, including the plotter time.

The photo tool requires no set up. The bottom sheet is placed on the registration pins in the vacuum frame. The resist-coated sheet of metal is placed on top of it and butted against the registration pins. The top sheet of the tool is placed on the registration pins. The frame is closed and squeegeed; a vacuum is drawn and the plate is exposed. The cycle time is one minute.

Cycle Times

When the stamping press is released for production, they can make about 40 parts per minute .all day long. So, in an 8 hour shift, they can make about 20,000 parts.

In photo etching, after the plate is exposed in printing, the sheets are sent through developing where the unexposed resist is washed away. The developed sheets go into the etching line, one after the other, making about 800-850 parts per hour. 6,400 or so parts per 8 hour shift.

For CC Star, laser cutting can produce about 80 parts per hour and waterjet makes about 30 parts per hour.

From a tooling and process standpoint, the photo etching and stamping processes are very different.

Lets look at the cost differences between chemical etching and metal stamping.

Heres the price comparison for CC Star produced in .020 stainless steel:

|

|

Photo Etching |

Metal Stamping |

Laser Cutting |

Water Jet |

|

Tooling |

$235 |

$10-$13,000 |

N/A |

N/A |

|

Cycle Time |

850 Pcs/Hr |

2400 Pcs/Hr |

80 Pcs/Hr |

30 Pcs/Hr |

| 1000 pcs | $2.03 | $3.85 | $2.03 | $3.50 |

| 5000 pcs | $1.96 | $1.95 | NQ | NQ |

| 10000 | $1.81 | $1.80 |

In this particular case, due to the complexity of the part, the amortization of the stamping die expense would require up to 1.3 million parts to be made.

If you are ready to find out how your application compares: