Etching, Stamping, Water jet or Laser: Which to Choose?

One of the questions we hear a lot is: How do I know whether stamping, laser, water jet or etching would be the best option for my project?

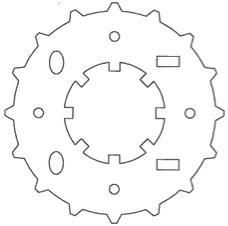

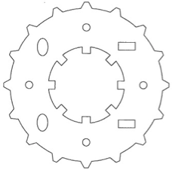

We decided to find out. We made up a part-we call it the CC star- it's a little stupid-looking but it serves the purpose.

We sent it out to several shops and asked them to quote making it in .020 stainless. The part is about 2.75 inches in diameter.

We sent it out to several shops and asked them to quote making it in .020 stainless. The part is about 2.75 inches in diameter.

This is what we learned:

| Etching | Stamping | Laser | Water jet | |

| Tooling/Set up | < $500 | ~ $10,000 | N/A | N/A |

| Cycle Time | 850 pieces/hour | 2400 pieces/hour | 80 pieces/hour | 30 pieces/hour |

| 1000 | $2..33 | $4.43 | $2.33 | $4.03 |

| 5000 | $2.26 | $2.24 | N/A | N/A |

| 10000 | $2.08 | $2.07 | N/A | N/A |

Not unexpectedly, stamping is a lot faster, potentially 2400 parts per hour for something like this. So, basically a half a day to produce 10K pieces. Laser and water jet definitely suffer by comparison, but is the (utterly unnecessary) complexity of "CC Star" that drives the issue. A simple washer might be a more fair competition.

Etching would be about 800 parts per hour regardless of the part complexity- a washer would have the same cycle time. So, a little less than 2 days for 10K parts. And, if you ordered 5000 or more parts, we wouldn’t charge you for the tool.

Here's the thing: the etching process is completely agnostic regarding part complexity. Complexity does not affect either the tooling cost or the cycle time at all. We make filters for French press coffee makers. Zillions of holes. All of them free.

'I'm not sure whether it is possible even to make a stamping die for a coffee filter like that. And, if it is possible, the cost would likely be astounding, with little-if any-impact on cycle time or part cost. (The burrs would be a problem, though.)

Other considerations:

- Stamping will raise burrs and may cold-work the metal.

- Laser will leave heat affected zones in the cut areas that may need to be cleaned up.

- Water jet will leave somewhat ragged edges as the pressurized cutting slurry contains abrasive material.

- The part complexity reduces cycle times for laser and water jet, precluding high volume.

- The cost of the stamping die is a relatively high barrier.

So, the math works out that you’d have to stamp a million of these widgets to amortize the cost the of the stamping die compared to etching them.

Each of these processes has a sweet spot:

- Water jet is the brute force solution for heavy gauges of metal and non-metallic materials.

- There are a multitude of laser solutions that are optimized for cutting both metal and non-metallic materials. Lasers are particularly good at cutting long runs very fast; they have largely replaced punch presses for most sheet metal fabricating tasks,

- Stamping is the high volume winner, as long as you can cover the tooling cost.

- Etching is a very versatile metal cutting process and is suitable for a wide range of alloys. Part sizes can range from .020" diameter to 24" x 58" panels in thicknesses from .001" to .040" for steel, .065" for copper and up to .080" in aluminum.

Feel free to contact us with any questions, or if you are ready to price your project: